The Volunteer State is living up to its name and has become the number one state in the Southeast U.S. for investments in electric vehicles (EVs). Ford, Volkswagen, and General Motors (GM) all have EVs in production in Tennessee, each planning to increase production and jobs in the state.

According to the U.S. Electric Vehicle Manufacturing Investments and Jobs report, Tennessee has created nearly 19,000 new jobs in the sector over the past eight years. It has received more than $16 billion in investments — with more than 191,000 EVs rolling off the state’s production lines in the last decade.

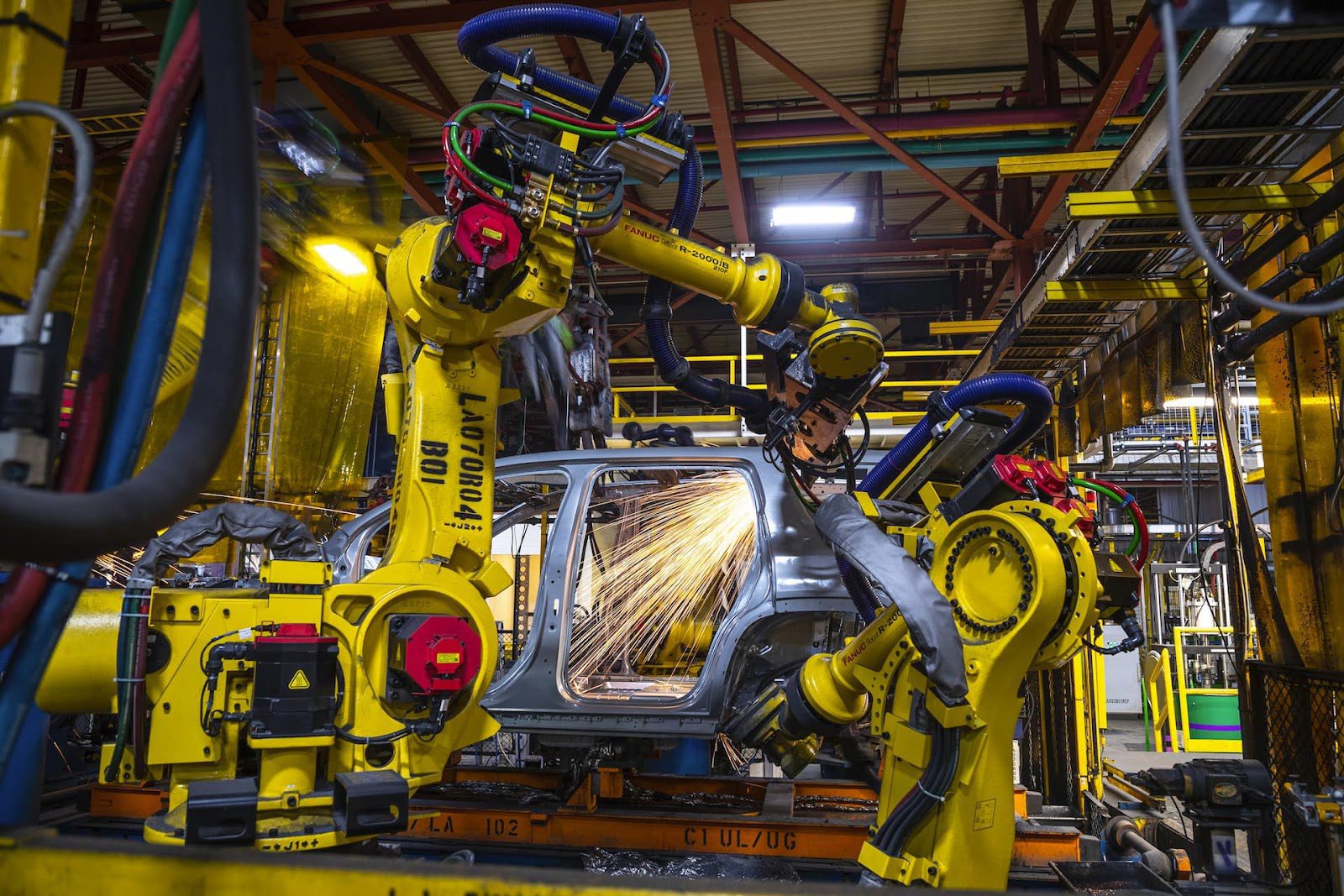

In Chattanooga, Volkswagen launched the production of its new electric SUV, with plans to produce around 90,000 cars by the end of this year. Just south of Nashville in Spring Hill, GM will transition its long-standing plant to become the company’s third EV manufacturing site.

Photo Courtesy GM

“We are committed to investing in the U.S., our employees, and our communities,” Mary Barra, GM chairman and CEO, said in a statement. “These investments underscore the success of our vehicles today and our vision of an all-electric future.”

On the west side of the state, Ford Motor Company is constructing a new plant that will produce a half million EVs each year.

The new Ford plant — known as BlueOval City — outside Memphis will add 6,000 new jobs and an approximate $5 billion to the Tennessee economy.

“Ford’s decision to bring BlueOval City to West Tennessee is a testament to our state’s skilled workforce and leading role in the future of American automotive manufacturing,” Gov. Bill Lee said in a statement. “With the single largest investment in state history, this historic project brings thousands of jobs and new opportunities for Tennessee families to thrive.”

Photo Courtesy GM

BlueOval City is backed by battery supplier SK Innovation and has a goal to produce 2 million EVs annually by 2026. The plant also promised to recycle and reuse batteries via a cost- and environmentally-saving collaboration with Redwood Materials.

“Increasing our nation’s production of batteries and their materials through domestic recycling can serve as a key enabler to improve the environmental footprint of U.S. manufacturing of lithium-ion batteries, decrease cost and, in turn, drive up domestic adoption of electric vehicles,” JB Straubel, Redwoods Materials CEO, said in a statement.

“Redwood and Ford share an understanding that to truly make electric vehicles sustainable and affordable, we need to localize the existing complex and expensive supply chain network, create pathways for end-of-life vehicles, ramp lithium-ion recycling, and increase battery production, all here in America,” he continued.

Photo Courtesy Ford

BlueOval City will also be Ford’s very first carbon-neutral vehicle manufacturing and battery plant.

It will be the home base for “Trust the Truck,” also known as Project T3, the second generation of Ford’s electric truck, an EV that has been in high demand with low supply.

“Project T3 is a once-in-a-lifetime opportunity to revolutionize America’s truck,” Jim Farley, Ford president and CEO, said in a statement. “We are melding 100 years of Ford truck know-how with world-class electric vehicle, software, and aerodynamics talent. It will be a platform for endless innovation and capability.”

Today, around 20,000 people are employed by EV manufacturers in Tennessee, with many more jobs expected soon. The Tennessee Department of Economic and Community Development told The Business Download: Clean Energy that nearly 32,000 EVs were produced in the state last year. It’s clear to see that Tennessee stands tall as a leader in the region by supporting thousands of new jobs, fostering innovation, and future-proofing the state’s economy.