Porsche has been making a concerted effort to be more environmentally friendly. The company wants to be carbon-neutral in its supply chain by 2030. It’s taken plenty of steps toward it, developing a carbon-free fuel, manufacturing several electric vehicles, and using solar energy for an independent microgrid at its headquarters in North America. One area we haven’t heard much about is the materials it uses in its car production.

Porsche is partnering with Swedish metal manufacturer H2 Green Steel in a strategic move to further their carbon neutrality. The steel is made using no fossil fuel or coal. Porsche will use the low-carbon steel starting in 2026. It’s the second deal H2 Green Steel and a Volkswagen AG company have signed; the first was with commercial vehicle producer Scania.

The World Steel Association says steel production contributes 7–9% of global emissions. To combat this, H2 Green Steel uses its namesake for clean power: hydrogen.

Green steel is produced through an electrolysis process where oxygen and hydrogen are separated. Through giga-scale electrolysis, enough hydrogen energy is generated to manufacture 5 million tons of steel by 2030.

The iron ore, the main ingredient in steel, is sent to a direct-reduced reactor. It is refined into direct-reduced iron (DRI) by exposing iron ore to hydrogen, and the oxygen in the ore reacts to form steam. The hydrogen from electrolysis powers this reduction process, eliminating emissions by 95%.

The DRI is transferred to an Electric Air Furnace. More hydrogen is used to heat DRI and steel scrap. It creates a melt of liquid steel. Carbon gas is injected into the furnace to lower electricity consumption, forming protective properties on the melt.

Photo Courtesy Christophe Dion

The liquid steel is moved to casting and rolling machines. It is formed into various shapes and sheets. Some hot-rolled steel is cold-rolled to change its thickness.

Porsche said it has been scaling back its steel use and switching to metals like aluminum. Yet the carmaker still needs steel for its mechanical properties.

Purchasing green steel is another step in decarbonizing its supply chain.

“Porsche is working towards a carbon-neutral balance sheet across the value chain for its cars by 2030,” said Barbara Frenkel, executive board member for procurement at Porsche AG, in a press release. “CO2-reduced steel plays a key role in our sustainability strategy. With the steel from H2 Green Steel, we aim to further reduce the CO2 emissions caused by this important material.”

According to Porsche, it used around 220,000 tons of steel in its vehicle production in 2022. With H2 Green Steel able to produce up to 35,000 tons of green steel a year for the carmaker, they will have a low-carbon source ready for use. From 2026, Porsche and various supply production material partners will be supplied with low-carbon steel.

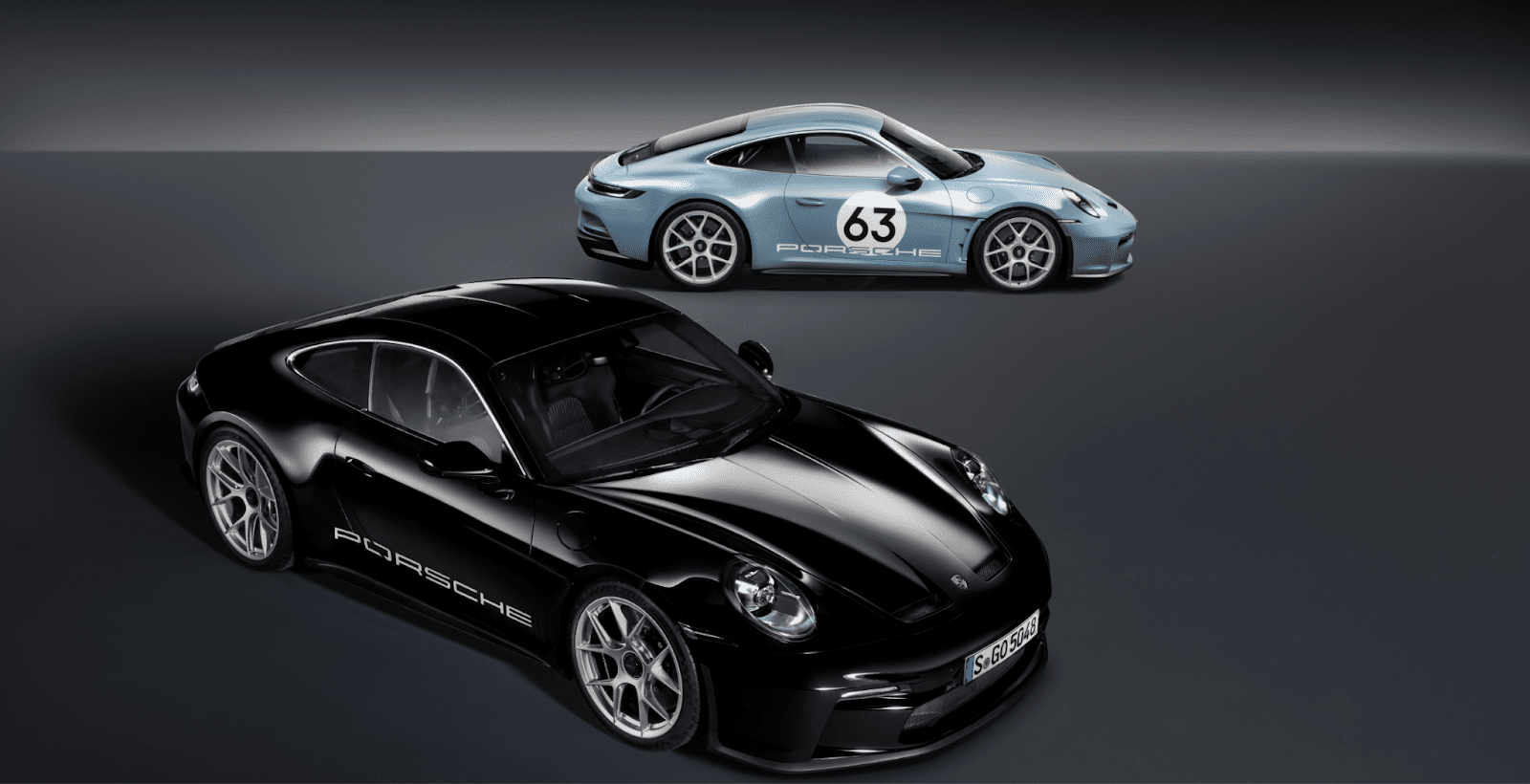

Photo Courtesy Porsche

The International Energy Agency (IEA) launched an Iron and Steel Technology Roadmap to show how the steel industry consumes energy and contributes to global warming. It also outlines strategies for how steel producers can reduce emissions. Using the “Step Up” efficiency methodology, maximizing scraps, and breakthrough technologies are considered the three best practices.

“Few brands are as iconic as Porsche,” Henrik Henriksson, H2 Green Steel CEO, said in a statement. “It stands for quality and a premium product. It’s also a company that is working actively towards a sustainable future, with clear expectations on how the supply chain contributes to that.”

“Having Porsche place an order for near zero-emission steel is a real boost both for us as a company but also the transformation of the steel industry, which has very much been driven by the demand from the automotive industry,” he continued.