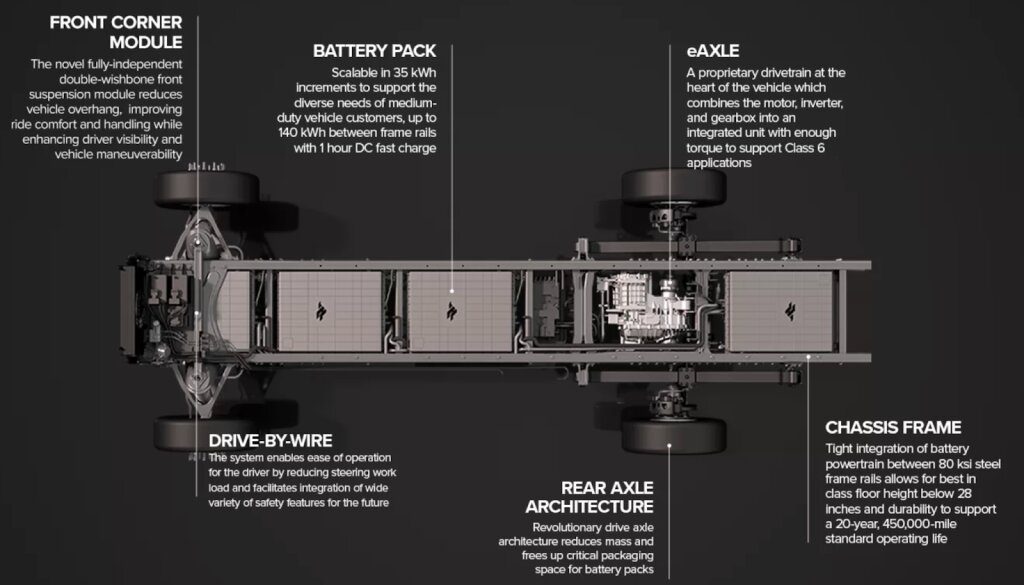

New electric vehicle (EV) manufacturer Harbinger is changing the cost of using medium-duty electric trucks. The Los Angeles-based company has invented the eAxle, a first-of-its-kind frame that combines the motor, gearbox, and inverter into one unit, bringing the overall price of a Harbinger truck down to the comparable cost of a gasoline or diesel-fueled truck. This innovation makes the transition to EVs easier financially for customers.

The eAxle is designed for use in commercial vehicles. The streamlined new frame, also called a chassis, is the vehicle’s overall main support system. This new approach reduces cost and improves the truck’s productivity and the driver experience with better suspension and a lower-to-the-ground ride.

It’s also safer than early EV designs, using steer-by-wire and brake-by-wire systems with advanced safety components and allowing more flexibility for driver positioning. Additionally, Harbinger vehicles use a liquid-cooled battery pack. By the end of 2024, Harbinger expects the eAxle to be available for medium-duty trucks, which include vans, box trucks, and RVs.

“Medium-duty vehicles serve as the backbone of the commercial transportation industry and are responsible for delivering tens of millions of packages and critical services every day,” said John Harris, Harbinger CEO. “But while this industry has experienced tremendous growth, fleet customers today face acute shortages of gas- and diesel-powered vehicles, and any meaningful supply of production-ready EV offerings is still years out. We are solving this problem head-on.”

Harbinger’s vehicles are designed to last 450,000 miles or 20 years and can be fully charged in one hour. They will cost no more than today’s equivalent fossil-fuel-powered commercial trucks.

“This industry is performing on decades-old technology that makes its daily rigors nearly unbearable for drivers and concentrates emissions of harmful pollutants in highly populated, residential, and business areas where they most acutely affect human health. We can no longer sit idle and watch that happen,” Harris said. “The reality is that technologies developed for the passenger or heavy-duty vehicle industries simply cannot be repurposed for the medium-duty segment.”

Harbinger is committed to bringing solutions into the medium-truck transportation sector. The company’s entire eAxle system reduces the cost of buying the vehicle and owning it over the truck’s lifetime. These results are because there is limited fuel cost, and maintenance is minimal.

These kinds of improvements are setting the stage for a shift in EV production to a new approach. The better design will focus on safety, logical operation, and driver comfort while improving battery life and speeding up the U.S.’s electric transition.

“The cost-effectiveness of the platform is a baseline, not a sacrifice,” Harris added. “Our platform will offer an enhanced level of efficiency, durability, safety, and performance over our competition and can be sold at a better price point because of our advantages of in-house component design and vertically integrated approach. This is how EVs should be built.”