Terabase Energy is transforming solar power plants with the launch of the Terafab, a fully-automated digital field factory for solar plant construction. The new system is capable of doubling productivity compared to traditional installation methods. It will also reduce electricity costs, improve work safety, and shorten project schedules.

“The Terafab system is a game-changer, offering a comprehensive solution that merges cutting-edge construction automation with a sophisticated digital system to transform the way solar power plants are constructed,” Matt Campbell, Terabase Energy CEO, said in a statement.

The system combines supply chain and inventory management systems, a twin of the project site, a field-deployed automated assembly line, and a digital twin of the physical project site. It includes installation rovers to create a fully automated system that works 24 hours a day, seven days a week.

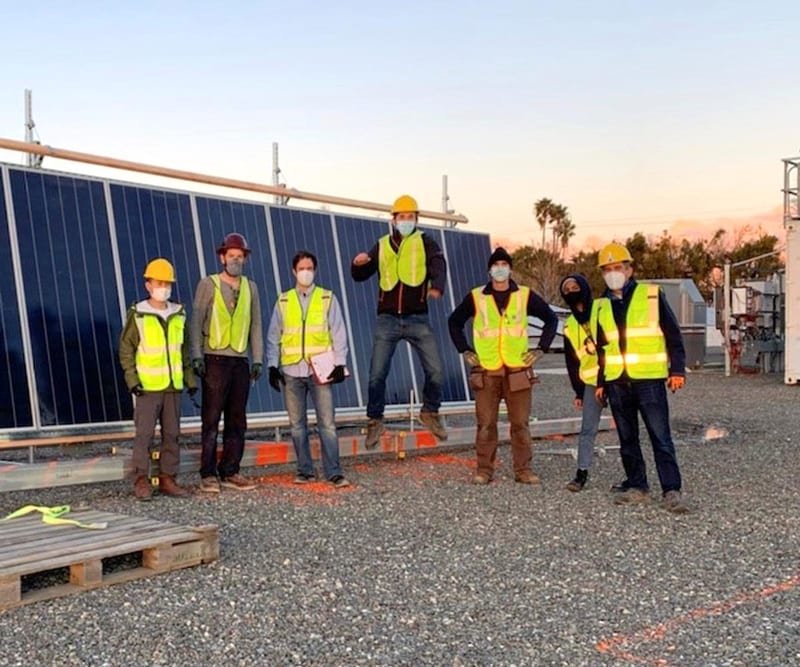

Photo Courtesy Terabase Energy

The Berkeley, CA-based company opened a new Woodland, CA, facility to manufacture the Terafab. It partnered with developer Intersect Power, construction firm Signal Energy, tracking hardware provider NEXtracker, and panel manufacturer First Solar on the factory.

“With emerging technologies and automation at the forefront of Signal Energy’s clean energy engineering and self-perform construction pursuits, Terabase’s solution complements our deployment strategy to improve in productivity, efficiency, and overall quality for our solar installations,” said Karl Schadlich, Signal Energy senior director of business development. “Above all, the Terabase team is continually looking ahead and pioneering the automation and solutions landscapes for the future of the renewable industry.”

Photo Courtesy Terabase Energy

The company says Terafab means faster construction across the board, with a speed-up of project ramp-ups, higher construction speeds, and a significant reduction of project schedule from start to finish. It also means improved worker safety and health by reducing the manual lifting of heavy solar panels and steel components. The firm also points out that the product can improve worker health since much of that work is often done outside in harsh weather conditions like extreme heat or winter cold.

Overall, Terabase Energy says its new technology doubles labor productivity, an essential asset since the solar industry is currently experiencing labor shortages.

Photo Courtesy Terabase Energy

Partners point to how these advantages and improvements add up to greater productivity with less risk and a significant enhancement to the industry’s sustainability. That means the cost of producing solar energy will decrease, sending savings along to consumers. The easily-replicated and quickly-deployed Terafab is designed to support the industry’s recent exponential growth.

“Our collaboration with Terabase on their Terafab technology exemplifies our commitment to deliver industrial-scale, clean infrastructure to combat the climate crisis,” Sheldon Kimber, Intersect Power CEO, said in a statement. “The Terafab system is also revolutionary for the health and safety of our partners in the field.”

“This technology will allow for higher quality and consistency of finished products and improved handling of packaging and materials, resulting in a more sustainable solar industry for all stakeholders for years to come,” he continued.

The Terafab system will be deployed beginning in the third quarter of 2023.