According to estimates cited by the University of Chicago, buildings account for roughly 30% of global energy consumption and emit 10% of all global greenhouse gas. About half of this energy footprint is due to regulating the temperatures of interior spaces. The rise of high-tech “smart” buildings will help reduce the footprint by making buildings more energy efficient and sustainable.

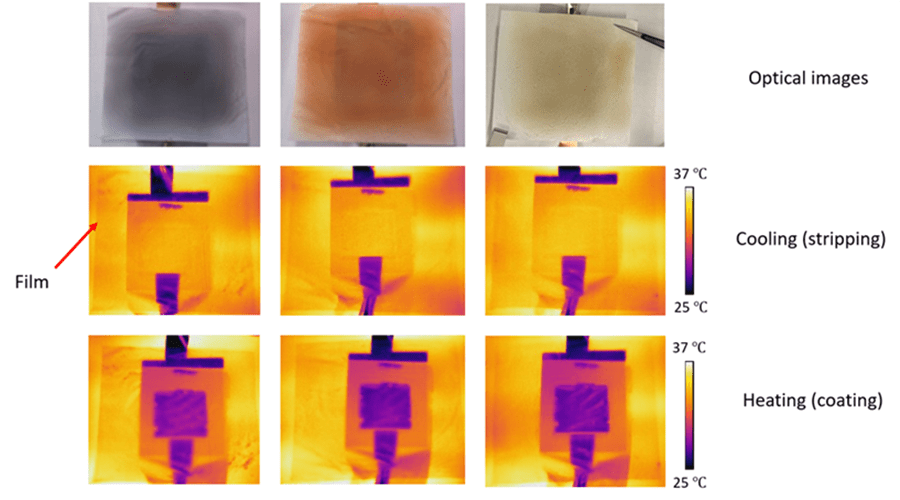

One of the latest advances in smart-building technology comes from researchers at the University of Chicago’s Pritzker School of Molecular Engineering (PME). They’ve designed a building material that changes its infrared color based on the outside temperature. On hot days, it can emit up to 92% of the infrared heat it contains, helping cool the inside of a building. It emits only 7% of its infrared on colder days, helping to retain a building’s warmth.

Photo Courtesy pme.uchicago.edu/Hsugroup

The idea behind the research is to save on energy costs by letting the building control the indoor temperature.

“We’ve essentially figured out a low-energy way to treat a building like a person; you add a layer when you’re cold and take off a layer when you’re hot,” said Po-Chun Hsu, the University of Chicago assistant professor, in a news release. “This kind of smart material lets us maintain the temperature in a building without huge amounts of energy.”

Hsu led the PME team’s research, which was published in “Nature Sustainability.” The new substance consists of an ultra-thin film that can change its infrared color and ability to emit infrared heat, which is the invisible heat that radiates from people, objects, and the sun.

The non-flammable electrochromic building material contains a layer that can take on solid copper, which retains most infrared heat, and a watery solution that emits infrared heat.

As Fast Company reported, one possible scenario is that the material could be linked to a thermostat and automatically trigger a switch whenever the outside temperature dips below or above a set number. At any predetermined temperature, the system can use a tiny amount of electricity to trigger a chemical shift between the solid and liquid.

Photo Courtesy pme.uchicago.edu

As part of its research, the team also created models of how the material could cut energy costs in typical buildings in 15 U.S. cities. They found that in an average commercial building, the power used to induce electrochromic changes in the substance would be less than 0.2% of the total electricity consumption but could save 8.4% of the building’s yearly HVAC energy usage.

“Once you switch between [the solid and liquid] states, you don’t need to apply any more energy to stay in either state,” said Hsu. “So for buildings where you don’t need to switch between these states very frequently, it’s really using a very negligible amount of electricity.”

Photo Courtesy Benjamin Suter

The team’s work is part of a broader global effort to make buildings more energy efficient. For example, scientists are researching smart windows that can switch back and forth between absorbing the sun in the winter and reflecting it in the summer. The difference with the University of Chicago research is that its material can be applied to multiple items. It can sit on any surface, inside a building and on the external façade.

As of late January, Hsu’s team had only created small pieces of the material, which measure about six centimeters. Further out, they expect many patches could be assembled into larger sheets.

“For a long time, most of us have taken our indoor temperature control for granted without thinking about how much energy it requires,” Hsu said. “If we want a carbon-negative future, I think we have to consider diverse ways to control building temperature in a more energy-efficient way.”